evg eps 3d construction wire mesh wall panel China supplier whatsapp+8613503293959

3D panel is a new type of building wall material. It can replace the brick wall to be used as load-bearing walls, non-load-bearing walls and floors, balconies and so on. It has features of expanding building area (10% -15%), noise insulation, heat insulation, earthquake resistance waterproof, simple installation, light weight,etc. All these features greatly reduce the cost of the project.

Tel:+86 13503293959 Skype: fatimasjz

Whatsapp / Wechat:+86 13503293959

Meshes

Panels can be supplied with wire meshes having different diameters, surface treatment (hot or cold galvanizing) and different geometrical characteristics.

All the processes involved in the production of the elements composing the 3d panel system are continuously subjected to the checks provided for by the ISO regulations.

We have our testing report of wire strength. Wire mesh resist the vertical pressure and diagonal wire resist shearing force.

Panels can be supplied with wire meshes having different diameters, surface treatment (hot or cold galvanizing) and different geometrical characteristics.

All the processes involved in the production of the elements composing the 3d panel system are continuously subjected to the checks provided for by the ISO regulations.

We have our testing report of wire strength. Wire mesh resist the vertical pressure and diagonal wire resist shearing force.

|

Tel:+86 13503293959 Skype: fatimasjz

Whatsapp / Wechat:+86 13503293959

|

Polystyrene (EPS)

The base element of the building system is a self-extinguishing foam polystyrene, suitably shaped, used both as a disposable form and as an insulating layer.

The EPS (sintered foam polystyrene) is made up of carbon, hydrogen and, for 98%, air. It is realized starting from the polymerization of styrene, a monomer obtained from oil and present in common food too (ex.: wheat, strawberries, meat, coffee). The latter, before being foamed, shows itself in the shape of little transparent pearls.

Thickness, shape and density of the Emmedue panel polystyrene core may change according to specific requirements. The minimum density normally used is equal to 15 kg/m³.

The base element of the building system is a self-extinguishing foam polystyrene, suitably shaped, used both as a disposable form and as an insulating layer.

The EPS (sintered foam polystyrene) is made up of carbon, hydrogen and, for 98%, air. It is realized starting from the polymerization of styrene, a monomer obtained from oil and present in common food too (ex.: wheat, strawberries, meat, coffee). The latter, before being foamed, shows itself in the shape of little transparent pearls.

Thickness, shape and density of the Emmedue panel polystyrene core may change according to specific requirements. The minimum density normally used is equal to 15 kg/m³.

|

Tel:+86 13503293959 Skype: fatimasjz

Whatsapp / Wechat:+86 13503293959

|

Plaster

Once the 3d panels have been installed, they are anchored and finished with the application of light concrete on both of their sides. In this way we realize buildings with load-bearing walls consisting of two reinforced concrete plates made integral by a thick network of connectors, with an insulating core.

When single panel is finished, , by applying on each side a layer of spritz-beton (water, concrete and sand) having characteristic resistance of 25 Mpa at least.

As a load-bearing element, the double panel and the floors are finished during the installation with a cast of suitably resistant concrete into the polystyrene plates.

Should not the panels carry out a load-bearing function, a concrete-based plaster, even a pre-mixed one, is applied for a thickness of at least 25mm.

Once the 3d panels have been installed, they are anchored and finished with the application of light concrete on both of their sides. In this way we realize buildings with load-bearing walls consisting of two reinforced concrete plates made integral by a thick network of connectors, with an insulating core.

When single panel is finished, , by applying on each side a layer of spritz-beton (water, concrete and sand) having characteristic resistance of 25 Mpa at least.

As a load-bearing element, the double panel and the floors are finished during the installation with a cast of suitably resistant concrete into the polystyrene plates.

Should not the panels carry out a load-bearing function, a concrete-based plaster, even a pre-mixed one, is applied for a thickness of at least 25mm.

|

Tel:+86 13503293959 Skype: fatimasjz

Whatsapp / Wechat:+86 13503293959

|

Specification

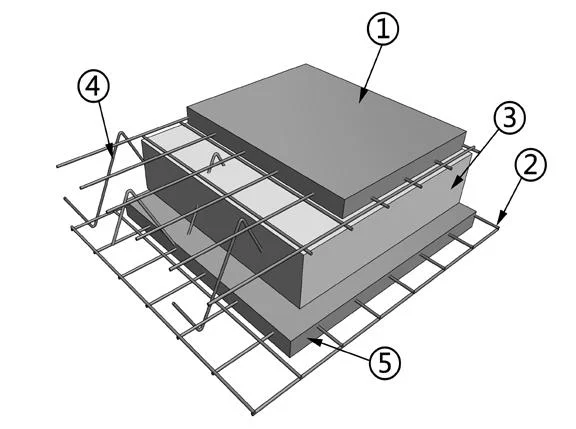

3D wire panel after shotcrete has the following five components (as Figure 2):

1. The outer layer of shotcrete.

2. Welded reinforcing mesh of high wire.

3. The core of expanded polystyrene sheet.

4. Diagonal wire (stainless or galvanized wire).

5. The inner layer of shotcrete

1. The outer layer of shotcrete.

2. Welded reinforcing mesh of high wire.

3. The core of expanded polystyrene sheet.

4. Diagonal wire (stainless or galvanized wire).

5. The inner layer of shotcrete

| EPS Core | Length:2.0-6.0m |

| Width:1.0-1.20m | |

Thickness: 50mm (for walls),

100mm (for the internal load- bearing walls), 120mm (for exterior wall).

| |

| Weight: 10-25kg/cbm | |

| Wire Mesh | Reinforcing welded mesh of high-wire |

| Wire diameter: 2.0-4.0mm | |

| Mesh size: 50 × 50mm, 50 × 100mm, 100 × 100mm | |

| Diagonal Wire |

Material:Stainless steel

Hot-dipped galvanized

Electro-dipped galvanized

|

| Turss wire type | |

| W wire type | |

| Distance between mesh and foam board | 10-16mm (for walls), 20mm (for load-bearing walls) |

Features

Advantages of 3D Wire Mesh Panel

1. Thermal insulation

Our constructions perform brilliantly in both insulation and load-bearing functions: the thickness and density of the panel can be customised to deliver specific thermal insulation requirements.

Furthermore, the EPS core extends throughout the surface which makes up the building envelope eliminating thermal bridging.

For example, an wall with a finished thickness of about 15cm provides the same thermal insulation as an insulated solid masonry wall of about 40cm, with obvious advantages in terms of additional space.

Our constructions perform brilliantly in both insulation and load-bearing functions: the thickness and density of the panel can be customised to deliver specific thermal insulation requirements.

Furthermore, the EPS core extends throughout the surface which makes up the building envelope eliminating thermal bridging.

For example, an wall with a finished thickness of about 15cm provides the same thermal insulation as an insulated solid masonry wall of about 40cm, with obvious advantages in terms of additional space.

2. Earthquake resistance

Lab tests carried out on full-size prototype houses determined that our 3d structures withstand, completely undamaged, earthquake loads superior to seismic safety requirements. The prototype houses were also tested using both artificial and natural accelerograms with peak values over 1,0g, and came through unscathed.

The results obtained in the lab tests represent the scientific confirmation of what has repeatedly been observed in real-world earthquakes.

Buildings made using Emmedue panels are particularly lightweight, so have a low seismic mass, but are at the same time rigid due to two sheets of reinforced plaster that interact to create an enveloping ‘shell’ of the whole structure.

Lab tests carried out on full-size prototype houses determined that our 3d structures withstand, completely undamaged, earthquake loads superior to seismic safety requirements. The prototype houses were also tested using both artificial and natural accelerograms with peak values over 1,0g, and came through unscathed.

The results obtained in the lab tests represent the scientific confirmation of what has repeatedly been observed in real-world earthquakes.

Buildings made using Emmedue panels are particularly lightweight, so have a low seismic mass, but are at the same time rigid due to two sheets of reinforced plaster that interact to create an enveloping ‘shell’ of the whole structure.

3. Fire retardant

The quality of the foam polystyrene used for our panels is self-extinguishing and is perfectly encased by layers of reinforced concrete which coat the sides of the panel and inhibit combustion.

Fire resistance has also been verified in tests performed in various laboratories. For instance, a wall erected using a 80mm tk provides ReI 120 fire resistance, which means that for 150 minutes, the panel proved to be R = stability, E = resistance to fire and smoke, I = insulation.

The quality of the foam polystyrene used for our panels is self-extinguishing and is perfectly encased by layers of reinforced concrete which coat the sides of the panel and inhibit combustion.

Fire resistance has also been verified in tests performed in various laboratories. For instance, a wall erected using a 80mm tk provides ReI 120 fire resistance, which means that for 150 minutes, the panel proved to be R = stability, E = resistance to fire and smoke, I = insulation.

FAQ

1. What is expanded polystyrene (eps) insulation?

The insulation core body (normally of Expanded, non-flammable Polystyrene) is securely and precisely locked in the centre of the panel, not shiftable, even under high pressure caused by the sprayed-on concrete as a result of the truss wires pierced through the insulation core and being arranged in zig-zag-configuration. This results in perfect building quality, with uniform concrete thickness throughout, giving highest structural strength as well as minimizing cement consumption.

2. How to install expanded polystyrene (eps) panel?

Erection is quick and easy (no cranes needed) because the EVG-3D panels are light (a standard panel weighs around 13 kg). The construction method is simple, easy to understand and does not require skilled labor.

EVG-3D panels can be cut quickly to any size or to a particular shape to suit architectural design concepts. Cutting of openings for windows and doors can be done in a matter of minutes.

3. What is the advantage of reinforced wire mesh expanded polystyrene (eps) panel?

DESIGN FLEXIBILITY 3D panels can be easily molded to fit complicated architectural designs. Window & door frames are easily created by cutting the required openings in the panel itself. 3D Panels are manufactured for ease of use. Each panel can be installed in a matter of minutes by an unskilled laborer.

Packaging & Shipping

Packaging Details:

expanded polystyrene 3D mesh panels for construction system Packaging:

naked packing or according to the customer's requirments

Delivery Detail:

20-30 days after receive deposit

expanded polystyrene 3D mesh panels for construction system Packaging:

naked packing or according to the customer's requirments

Delivery Detail:

20-30 days after receive deposit

Our Services

1. Free sample

2. Factory direct supply price

3. Specification can be customized

4. Fast delivery

5. All accessories needed, like ir compressor, cement spray machine , rebar tying gun, panel cutting machine, mortar gun, etc.

评论

发表评论